- Investor Relations

- Management Information

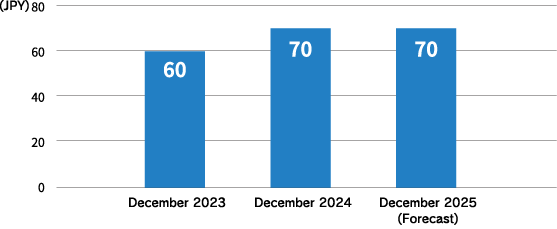

- Financial & Performance Data

- Financial & Performance Data

- IR Library

- Stock Information

- Other IR Information

Seibu Giken at a Glance

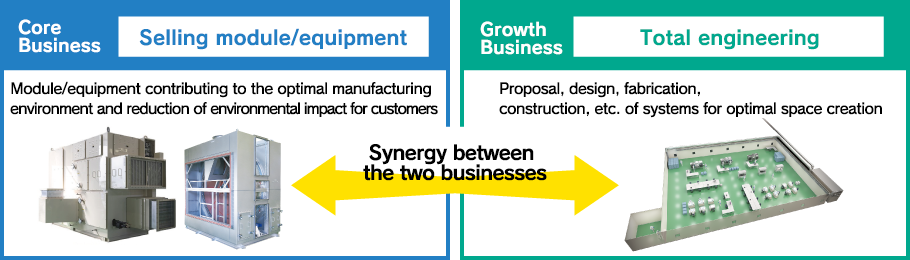

Seibu Giken's Business

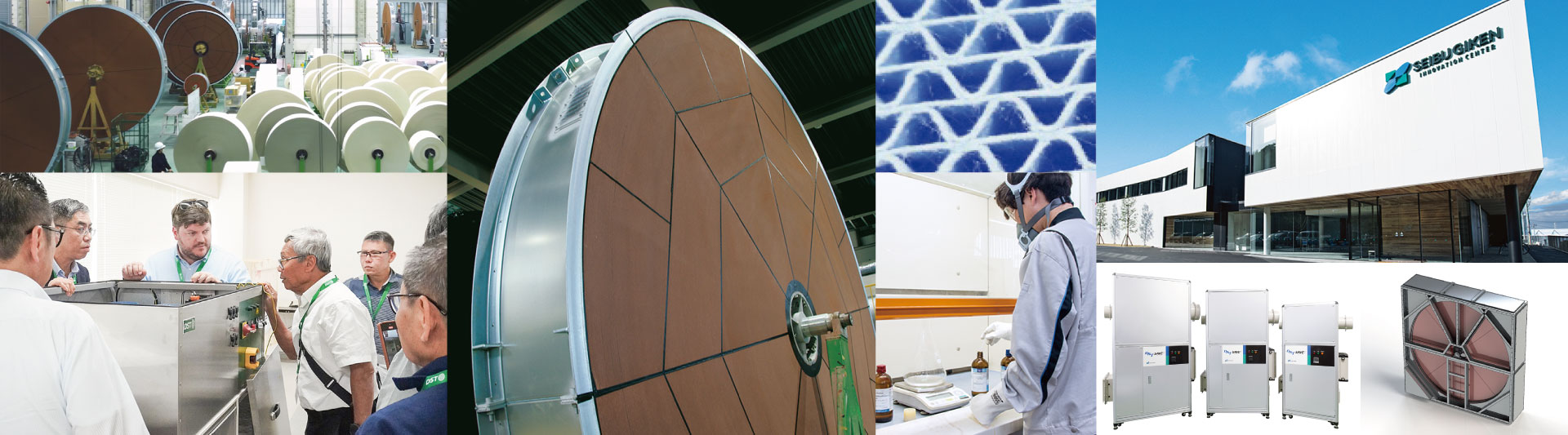

We provide equipment and systems for controlling air quality at factories, warehouses, buildings, etc. on a global basis.

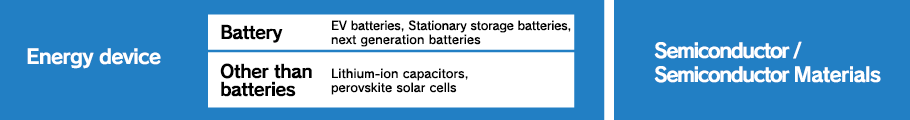

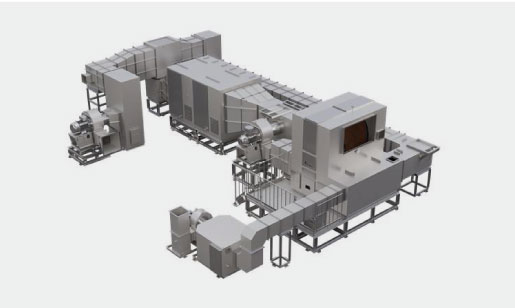

Seibu Giken provides global services such as the development, design, manufacture, sale, installation and maintenance of specialized air treatment equipment and systems, including Desiccant Dehumidifiers that enable strict humidity control in automotive battery manufacturing factories, etc. and VOC concentrators that selectively remove and concentrate volatile organic compounds (VOCs) that cause air pollution in semiconductor factories and automotive painting processes.

Main products

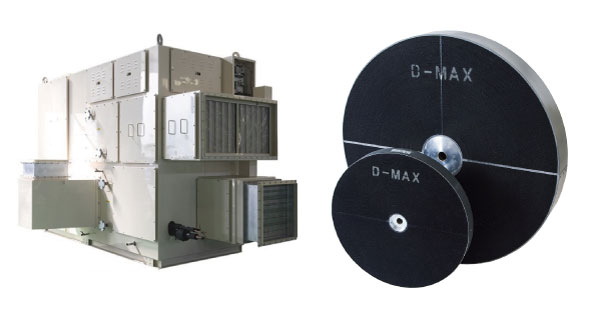

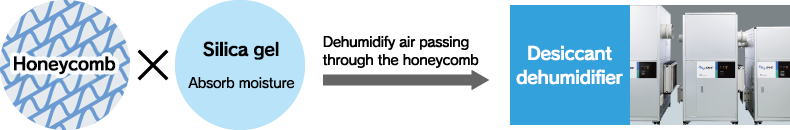

- Desiccant dehumidifier

-

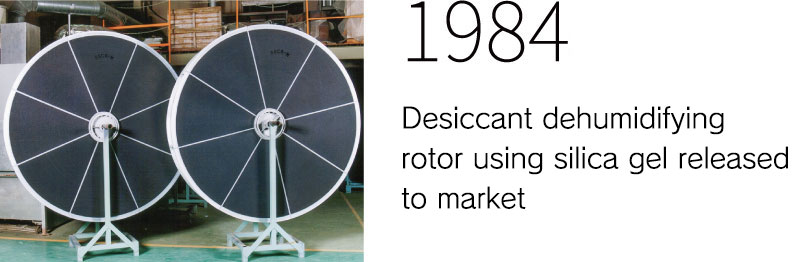

The core honeycomb rotor adsorbs moisture using silica gel or hydrophilic zeolite, thereby dehumidifying the air. Since air cooling is unnecessary, it achieves high efficiency and energy savings even in low-temperature or low-humidity environments.

-

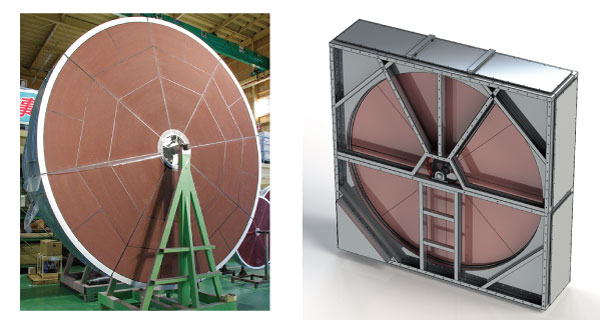

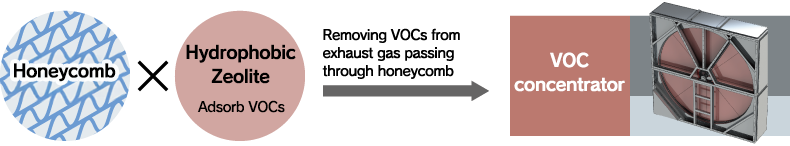

- VOC concentrator

-

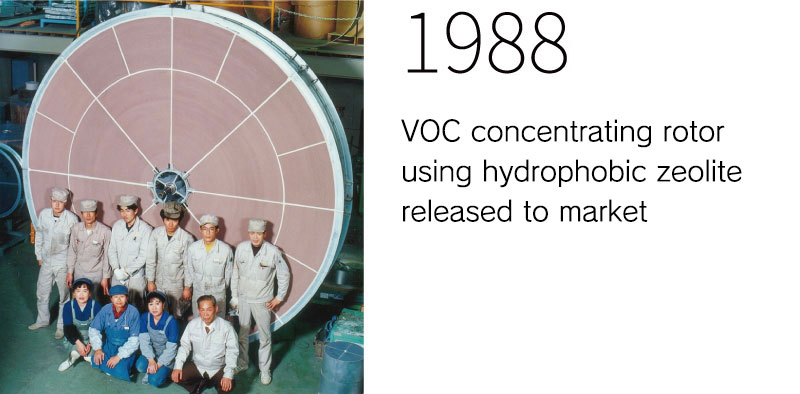

VOCs, which cause air pollution and are contained in exhaust gases from manufacturing plants for automobiles and semiconductors, are selectively adsorbed and removed by adsorbents attached to honeycomb rotors.

VOC concentrators achieve energy savings and cost reduction. -

- Total heat exchanger

-

The honeycomb rotor stores the heat and moisture (total heat) of the air exhausted from the air-conditioned room and transfers it to the intake air. As a result, the intake air is preheated and humidified in winter, and precooled and dehumidified in summer before being supplied to the room. By exchanging the energy lost in ventilation within the equipment, it contributes to energy conservation and CO2 reduction.

-

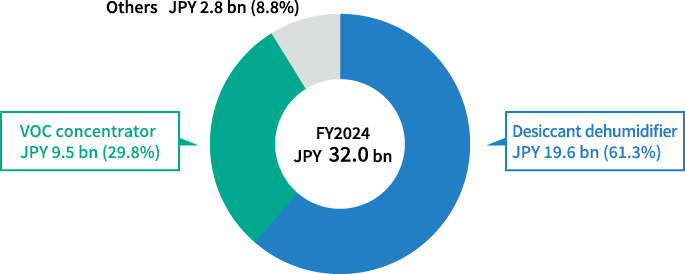

Sales by Product

Discover Seibu Giken

Seibu Giken's products control air quality in a wide variety of locations.

Seibu Giken in Numbers

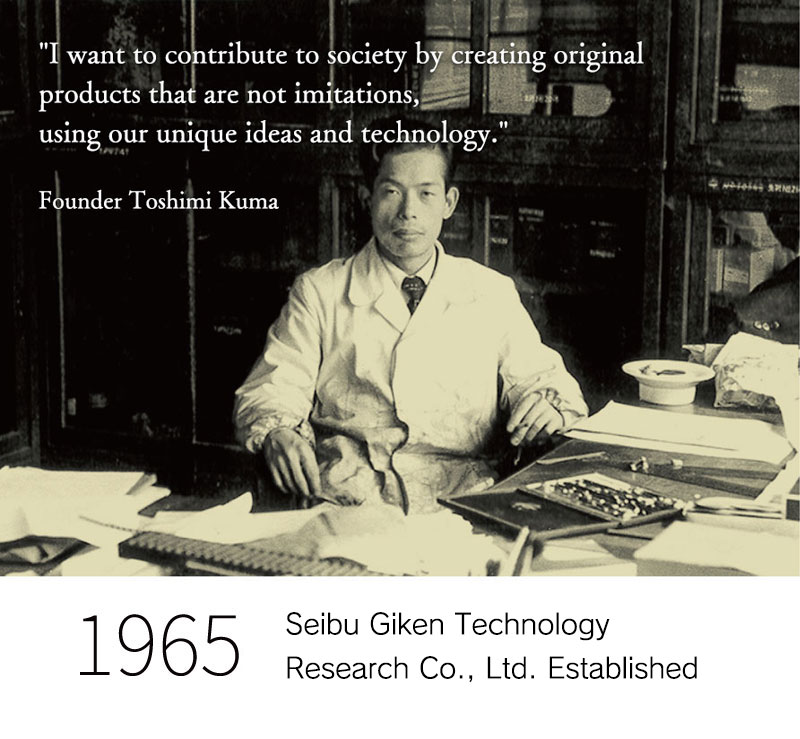

- 1965

- Founded

- JPY 32.0 billion

- Net sales

(FY2024)

- JPY 4.0 billion

- Operating profit

(FY2024)

- 12.6%

- Operating profit margin

(FY2024)

- 67%

- Overseas sales ratio

(FY2024)

- 779

- Number of employees

Consolidated

(as of Dec. 31, 2024)

- 392

- Number of employees

Parent company

(as of Dec. 31, 2024)

- 12

- Group companies

(as of Jun. 30, 2024)

(includes parent company)

- 10

- Overseas subsidiaries

(as of Jun. 30, 2025)

- 6

- Overseas manufacturing base

(as of Jun. 30, 2025)

Seibu Giken's Strengths

Core technologies

Our core technology involves the molding of a honeycomb laminate that features three characteristics: low air resistance, superior strength, and a large surface area. Additionally, we have the technology to apply various functional agents to this honeycomb laminate to impart special functions. Our products utilize honeycomb rotors (rotating bodies) developed through our core technology.

- Products utilizing core technology

-

- Products utilizing core technology

-

Providing one-stop solutions for development, manufacturing, and after-sales service.

We provide one-stop solutions from the development and manufacture of honeycomb rotors, which are the core components of our products, to the assembly and sales of finished products, system construction, and maintenance.

By consistently offering solutions from development to maintenance, we can obtain customer needs and feedback, which we reflect in our product development, improvement, and proposal activities.

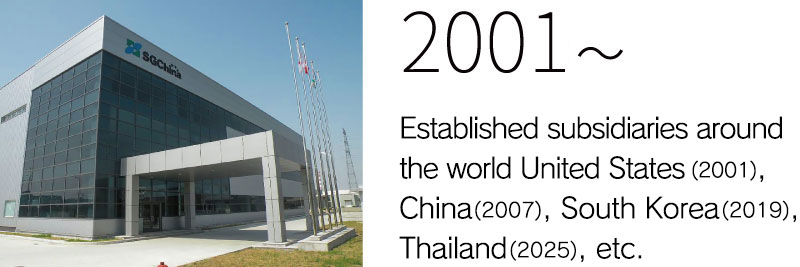

Global supply system

We have subsidiaries and manufacturing bases in Japan, Europe, Asia, the U.S. and elsewhere. We supply high-quality, high-performance products on a global basis while responding quickly and flexibly to the needs of customers in countries around the world.

The rotors, which are the core components of our products, are manufactured only in Japan and sent to manufacturing bases around the world to be assembled into modules or finished products.

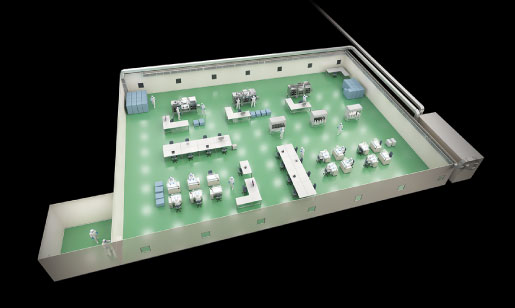

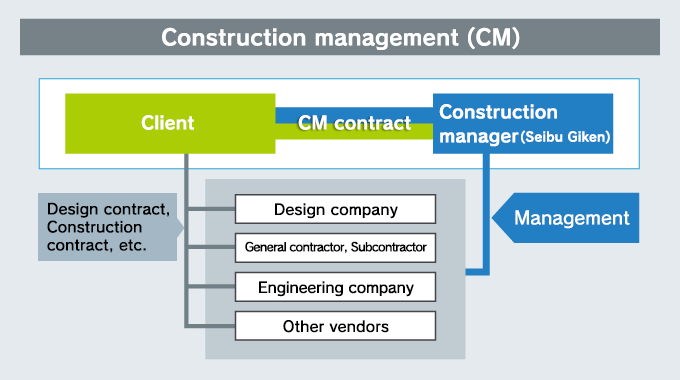

Total Engineering

We provide comprehensive services not only in the sale of equipment and devices but also in proposing, designing, manufacturing, constructing, and managing construction to create optimal spaces in the manufacturing process, such as dry rooms using desiccant dehumidifiers and solvent recovery systems using VOC concentrators.

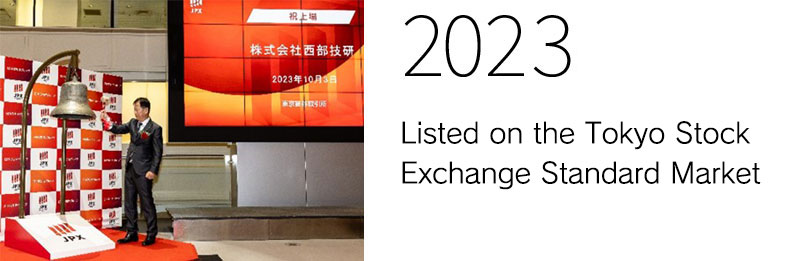

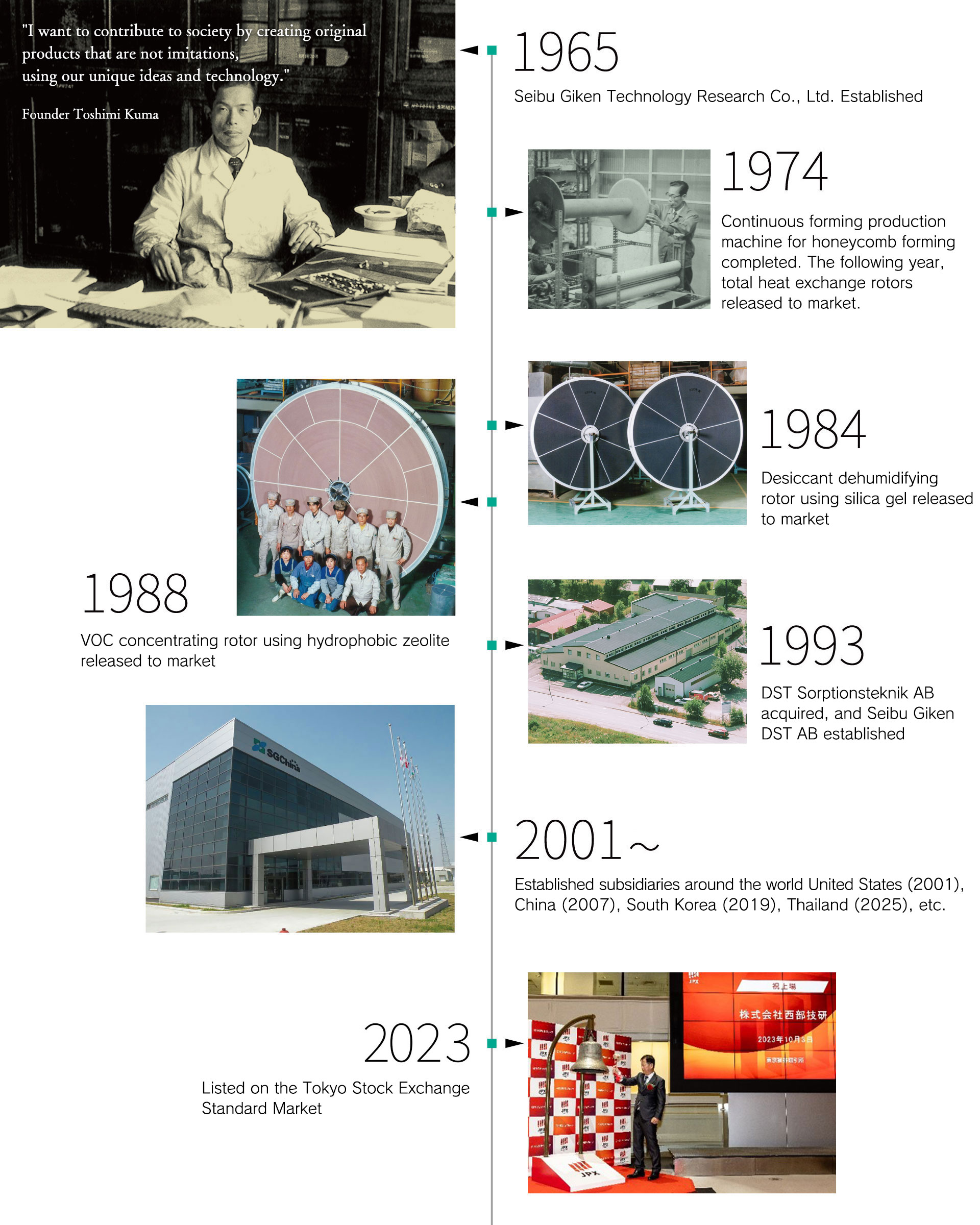

Seibu Giken's History

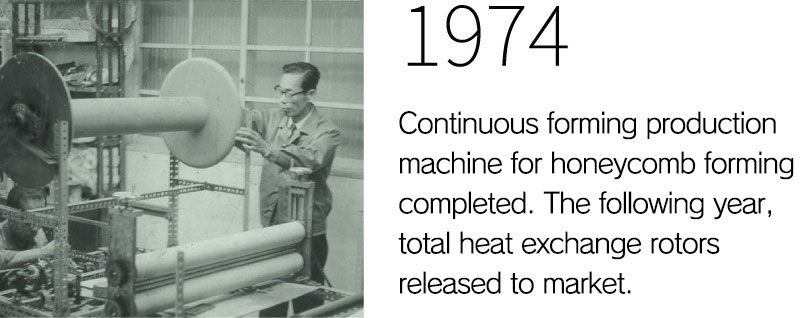

Toshimi Kuma, the founder, was working as a researcher at the Faculty of Engineering at Kyushu University. However, he wanted to move away from experiments and paper writing in academia to develop products that would be practically useful to the world. In 1965, he established "Seibu Technology Research Institute Co., Ltd.," the predecessor of our company. The oil shock of 1973 marked a turning point, drawing attention to energy issues. Since successfully commercializing total heat exchangers by establishing honeycomb molding technology in 1974, the company has continued to grow through global expansion and business development.

Milestones in Our Growth

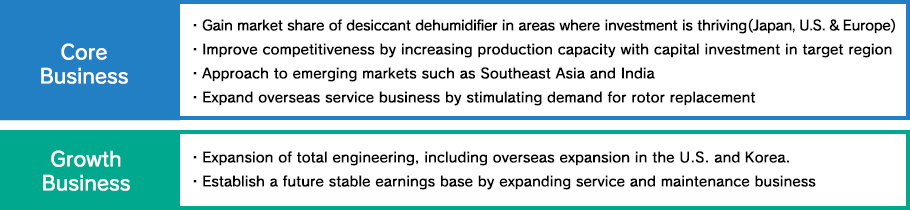

Medium-Term Management Plan

2024-2026

We have set a medium-term management plan covering the period from 2024 to 2026. This plan is based on three fundamental policies: expanding market share in core businesses, launching growth businesses, and strengthening group governance. We are implementing various measures to achieve these goals.

Growth Strategy

Aiming at sustainable profit growth by gaining market share in our core businesses in Europe and North America and by expanding total engineering business