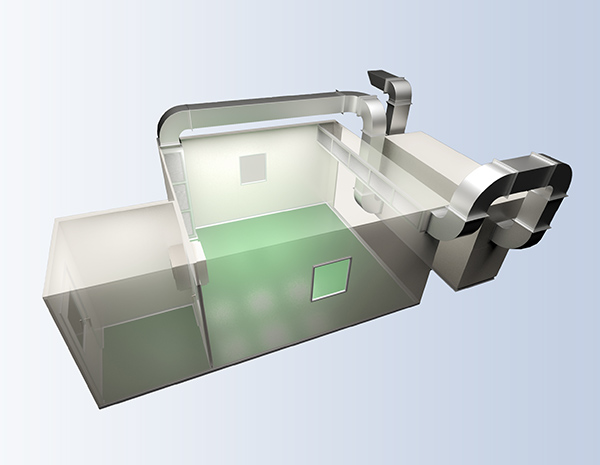

Products & SolutionsAfter-sales Service( available only in Japan )

Our team of skilled service professionals delivers meticulous maintenance and repair solutions, along with tailored proposals and support to meet customer needs.

Other services

Customers considering rotor replacement

Rotor replacementCustomers considering maintenance of other brands’ products

Maintenance of other brands’ productsScheduled maintenance

Benefits of Scheduled maintenance (preventive maintenance)

1. Prevention of sudden breakdowns

Regular inspections and planned parts replacement are crucial to avert sudden equipment failures and significant operational issues.

2. Capacity management

By conducting capacity measurements and optional rotor deterioration analysis—the heart of the machine—we can assess any deterioration in function and performance.

Reduced capacity could increase the running costs of the core equipment and surrounding system.

3. Energy-saving initiatives

We propose reducing operating costs by installing energy-efficient components as replacements.

To maintain energy efficiency and equipment performance, periodic inspections and parts replacement are recommended.

- Periodic inspection

Our field engineers offer a full range of support, from routine inspections and equipment assessments to essential repairs and component replacements.Periodic inspection: From once a year

- Swift response capabilities from locations across the nation

We respond quickly to sudden problems and emergencies. - Contracts are available at any time.

You can sign up at any time after delivery. Please feel free to reach out to us. -

Proposal of maintenance details

Beyond standard inspections, we tailor our maintenance recommendations to align with the specific equipment and installation conditions.For basic inspection details, please refer to the following maintenance information.